Composite (FRP) called complex material (full name is reinforced fiber complex material, referred as FRP). Reinforced fiber resin has 2 main components: 1st component is Essence, also resin. Essence commonly used is: unsaturated polyester resin, epoxy resin, Phenolic resins, vinyl ester; 2nd component is the reinforcement material, as well as reinforcement fiber such as: fiberglass, carbon fiber, aramid fiber, metal fiber.

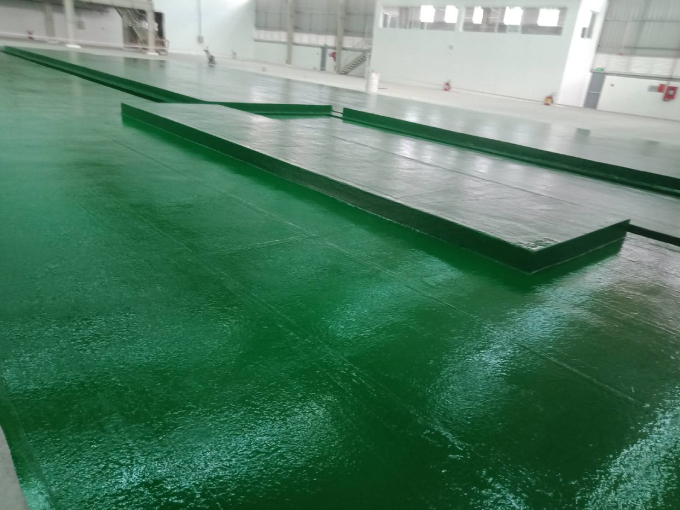

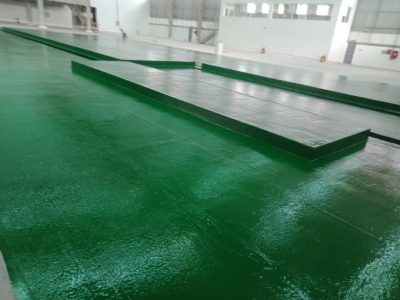

Composite materials, besides features such as high strength and light weight, it is also used to make products with different shapes according to customer’s design. FRP has superior corrosion resistance, can be resistant to most solvents, salt, alkali, acid, etc. So now, FRP have been used for many anti-corrosion applications especially positions require special corrosion resistance.

Properties:

• Corrosion and acid alkali resistant, superior chemical resistant

• Heat – resistant (80oC – 90oC), resistance to high pressure and severe chemical environments.

• High adhesion, high strength, easy construction

• High impact strength and extreme fatigue.